Products in foam

Production methods

Hot wire cutting

The possibilities of contour cutting of EPS expanded polystyrene (trade name Styrofoam, by the Dow Chemical Company) and Neopor are limitless. In all possible sizes (from milimeter, to multiple meters) and all quantities (from 1 piece to a returning mass series) Twinplast can make for you:

-

Simple 2D forms:

-

blocks and plates

-

cylinders and cones

-

waved plates

-

profiled plates such as: U-profile and L-profile

-

...

-

-

3D Letters and numbers!

-

complex 2D forms and shapes:

-

abstract forms (like a block with a square as base and a circle as top)

-

contours of animals and other shapes

-

any shape you could draw on paper without lifting up your pen

-

Contour cutting is very useful for protection packaging or advertising products and concrete shuttering and plenty more.

Platen in EPS en Neopor

in EPS.

.

Contour sawing

The possibilities of contour sawing of EPE, polyurethane or hard and soft foams or another material you prefer, are limitless. In all possible sizes (from milimeter, to multiple meters) and all quantities (from 1 piece to a returning mass series) Twinplast can make for you:

-

Simple 2D forms:

-

blocks and plates

-

cylinders and cones

-

waved plates

-

profiled plates such as: U-profile and L-profile

-

...

-

-

Letters and numbers!

-

Complex 2D forms and shapes:

any shape you could draw on paper without lifting up your pen.

Contour sawing is very useful for protection packaging or advertising products.

CNC Turning by the CNC operated Lathe

With our CNC operated lathe we can make every 3D figure with a round contour very easily by working on it as it rotates around its axis. Because of this, the process is much quicker than 3D milling.

When you would slice up an object and all the slices are circles (and not oval or rectangular), then you could make this object with the CNC lathe. So an orange or a carrot could be made, a banana not (for it is curved which makes it slices oval). The maximum diameter is 2700mm.

CNC Milling

CNC milling is scraping away material with a high velocity in a detailled fashion by using one or multiple rotating CNC operated fraises.

CONTOUR MILLING: Milling can be used to finish contour cut products (such as creating a partial hole in a plate), or cut shapes inside a product and letters when no incision may be made (like the inside of a 'O'). This can be done for single pieces or mass production.

3D MILLING: Twinplast can also mill complete 3D figures from a 3D design made with CAD/CAM systems or from a statue used as model that gets scanned by us. For creating large and complex 3D objects, milled parts are assembled together. Size is not important! We once milled a whale of 15m and we dare you to go bigger!

Milling can be used for a shuttering to pour your original design in concrete.

It can also serve as the basis for a mold in polyester.

3D milling can be done in a variety of materials such as EPS or Styrofoam (trademark of the Dow Chemical Company), soft & hard foam (like polyurethane), EPE/EPP, massive plastics (like polyethylene or POM) and aluminium or another material of your choosing.

Note that Twinplast does not paint or coat its products.

3D Scanning

With a scanner every possible 3 dimensional figure can be scanned (on condition that the scanner can reach all the corners of the object). This scanning can also be done at your home. The scanner remembers the distance of different points from the object to the scanner, and so a 3D point cloud gets created. After the scanning the image can be edited on the computer. From there, a 3D figure or mold for casting concrete can be milled from the scan or an adaptation of the original can be made for an artwork, or a database of an entire collection can be saved electronicly, or... .

Dit beeld werd ingescand. Op de volgende foto ziet u het resultaat!

De 3D versie op de computer van het ingescande Mariabeeld van de vorige foto.

Dit hoofd werd ingescand. Rechts ziet u het resultaat.

Het hoofd wordt ingescand. Dit levert verschillende zichten op die nog met elkaar verbonden moeten worden. Hiermee kunnen we een 3D puntenwolk maken.

Deze schroef werd ingescand. De verschillende zichten op het eindresultaat staan op de pc.

Thermoforming

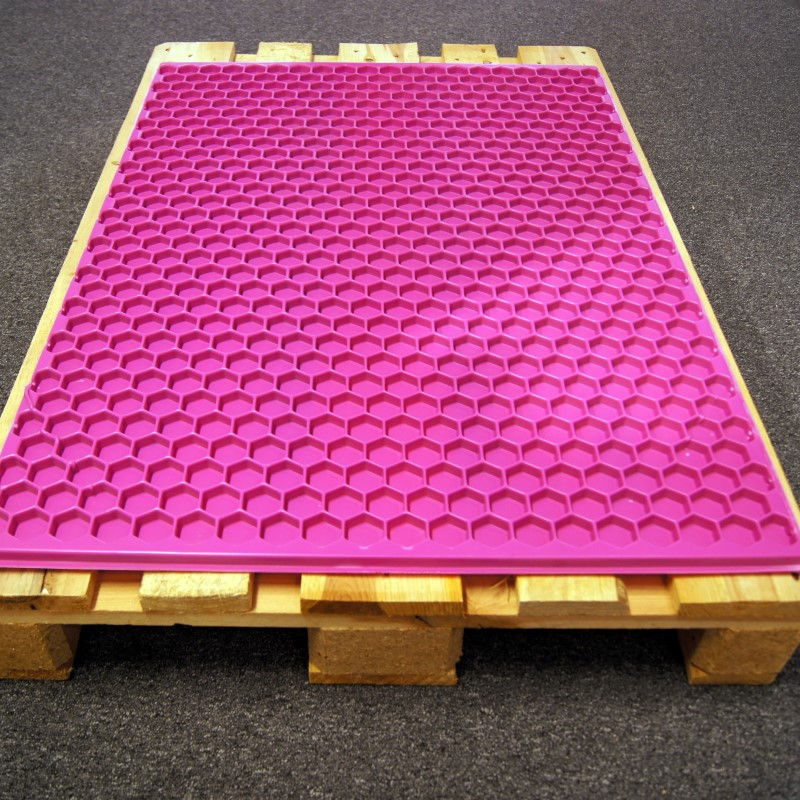

Vacuum thermoforming, is pulling foil, which has become elastic by heating, over a mold and sucking the air out of foil covered mold, making it vacuum. By cooling the foil maintains the shape of the mold. Afterwards the end product is cut by using punch presses.

The molds are milled in our own atelier, and also the foil is extruded by us. Because of this, it is easy to choose a raw material (PS or PP), a specific colour or even to add an addative substance which gets automaticly processed into the foil.

Vacuum formed trays can be made upto 1000 on 1200mm, what makes it ideal to create trays for pallets. Other formats of trays specifically shaped to fit into standard containers. The trays can be used for transporting car parts, or small medical bottles or containing food, ... Other shapes can be made aswell such as corner protecters or a display for presenting your products, and so much more...

voor 2 types luidsprekers te vervoeren.

voor taartjes

voor warme maaltijden te vervoeren. De tray houdt de maaltijd warm en is nadien makkelijk te reinigen.

voor op palletten.

op palletformaat voor auto-onderdelen met hun montage benodigdheden te transporteren.

voor op palletten met opzetranden.